您也許對徐州本地以下產品新聞也感興趣

- 硅鋼B30AHV1500現貨報價

- 寶鋼期貨DW270-35對照牌號

- 募捐舊衣回收箱實力雄厚

- 檔案室密集柜報價

- 1kg硅鋼零售廠家50WW270價格

- PDS873GH-1FA1DE-P-05AB-22MS1-LBA/G61廠家直銷-找索正自動化儀表

- 貨柜卸貨平臺 價格

- 發電機租賃/出售/回收(10KV-35KV高壓發電機)批發渠道

- 專業廠家直銷WP-LE3Q-T9094LL

- 到成都回頭車整車公司(2025)(安全快捷)

- 網上銷售【鑫康】樣品密集架

- 濟南藝考文化課【高考英語輔導】專業齊全

- 【檔案密集架歡迎電詢】

- 貴陽到物流返空車整車調配公司2025已更新(今天/熱聞)

- 藝考文化課補習-藝考文化課沖刺指導就業

當前位置:

鹿程國際貿易有限公司 >

徐州本地產品推薦News

無取向電工鋼板50WW250磁感值

更新時間:2025-01-21 15:28:30 瀏覽次數:13 公司名稱: 鹿程國際貿易有限公司

以下是:無取向電工鋼板50WW250磁感值的產品參數

| 產品參數 | |

|---|---|

| 產品價格 | 2/噸 |

| 發貨期限 | 3天內 |

| 供貨總量 | 50000 |

| 運費說明 | 電議 |

| 最小起訂 | 1 |

| 質量等級 | 精品 |

| 是否廠家 | 是 |

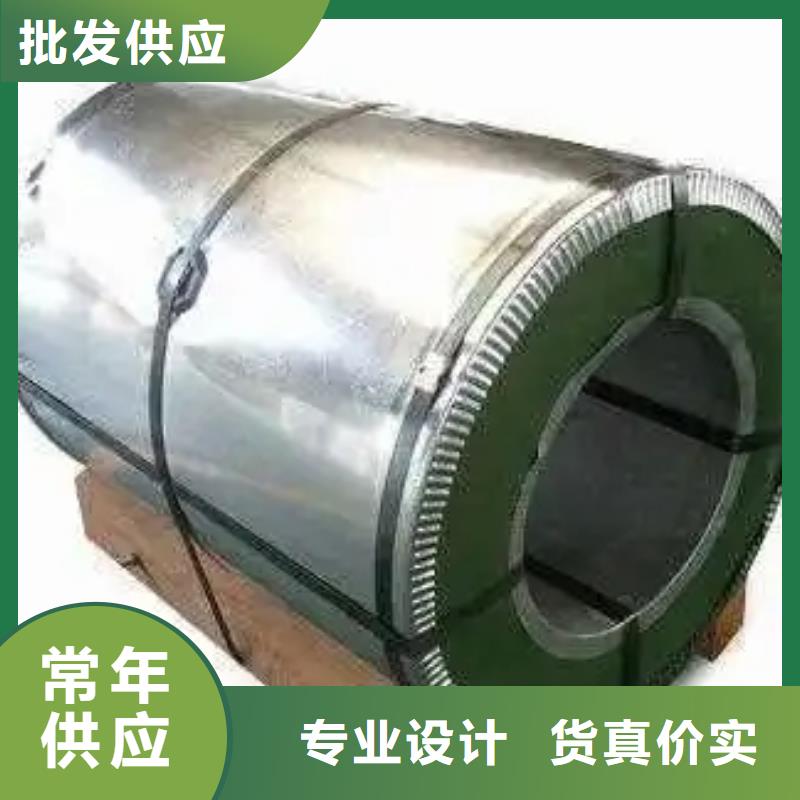

| 產品材質 | 冷軋 |

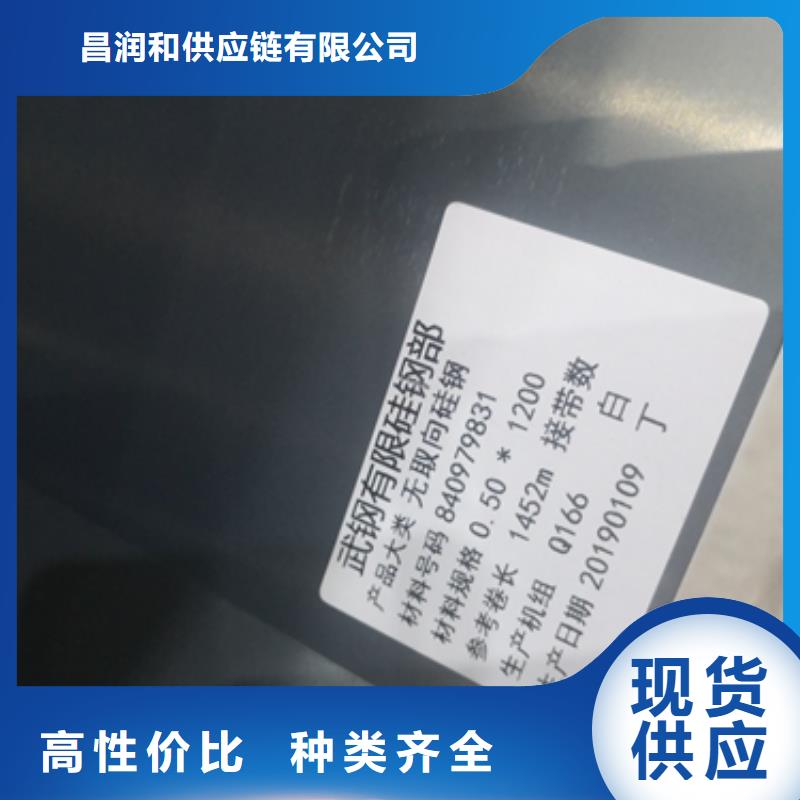

| 產品品牌 | 寶武日本進口 |

| 產品規格 | 0.08-0.65 |

| 發貨城市 | 上海武漢 |

| 產品產地 | 上海武漢 |

| 加工定制 | 粗加工 |

| 產品型號 | 多種 |

| 可售賣地 | 全國 |

| 質保時間 | 一年 |

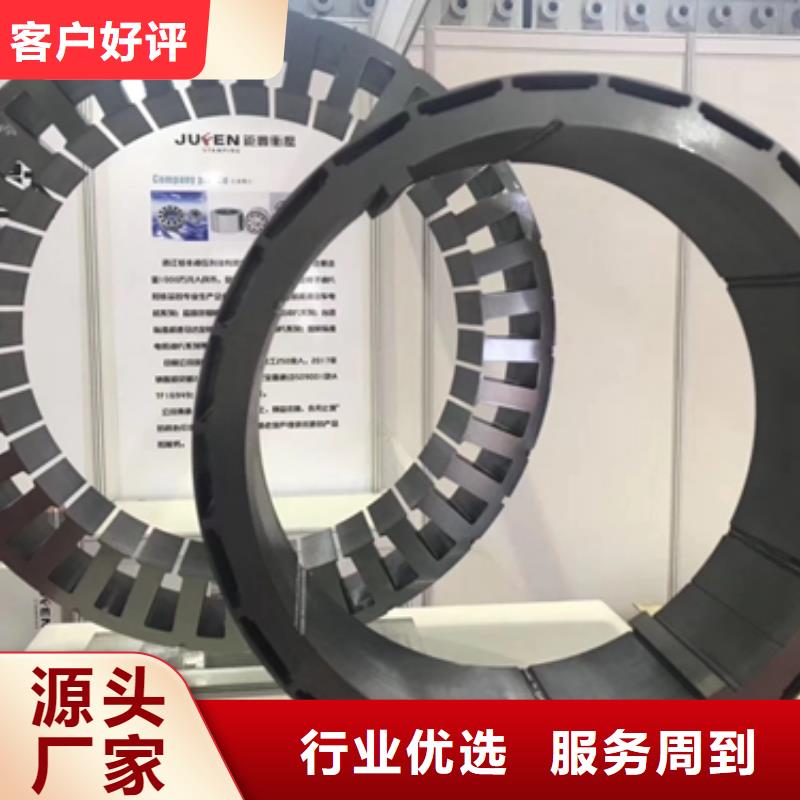

| 適用領域 | 電器馬達電機變壓器磁感器互感器穩壓器繼電器電磁開關新能源電機電動汽車變壓器軍工電機發電機組航天造船汽車等 |

| 是否進口 | 否 |

| 品名 | 電工鋼 冷軋無取向電工鋼 冷軋取向電工鋼卷冷軋取向硅鋼 取向電工鋼冷軋無取向硅鋼冷軋無取向硅鋼 |

| 規格 | 0.08 0.1 0.05 0.18 0.2 0.23 0.27 0.3 0.35 0.5 0.65 1.0mm |

| 包裝 | 原廠精包裝 |

| 用途 | 電器馬達電機變壓器磁感器互感器穩壓器繼電器電磁開關新能源電機電動汽車變壓器軍工電機發電機組航天造船汽車等 |

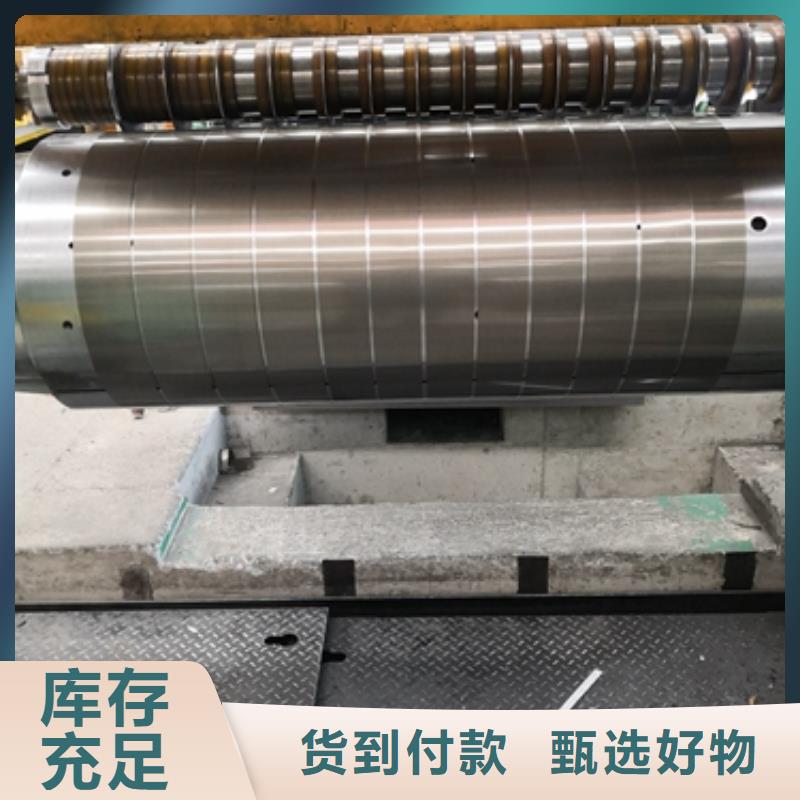

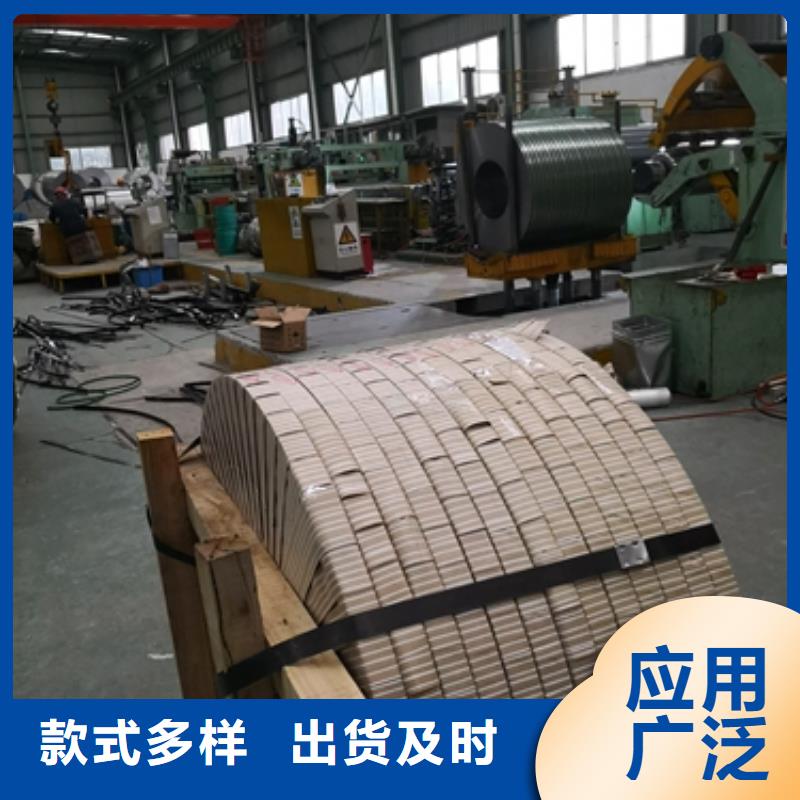

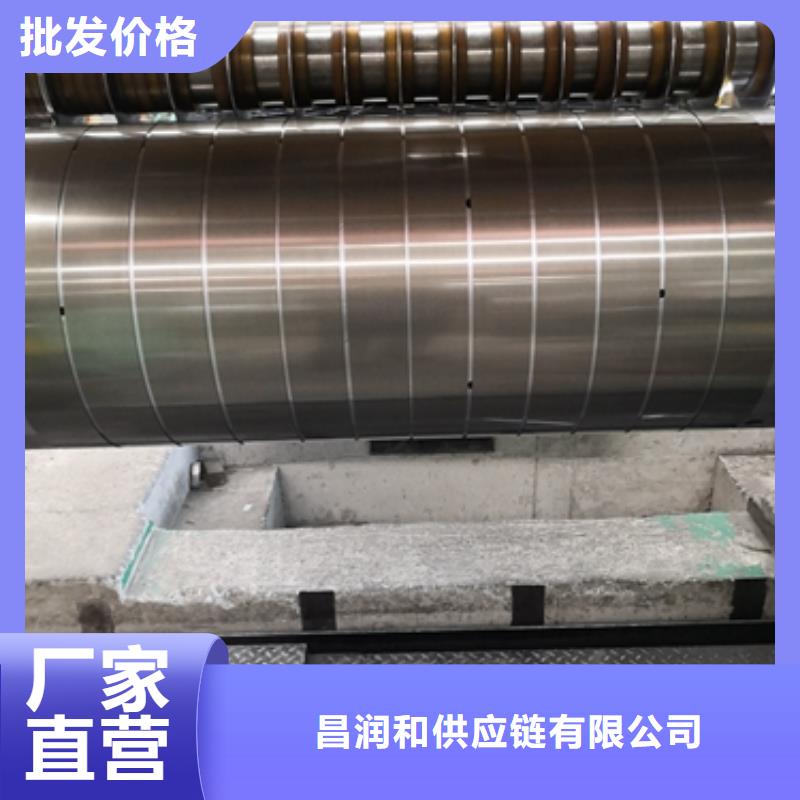

以下是:無取向電工鋼板50WW250磁感值的圖文視頻

無取向電工鋼板50WW250磁感值,鹿程國際貿易有限公司專業從事無取向電工鋼板50WW250磁感值,聯系人:鹿丙偉,電話:021-56152236、13764370568,QQ:871956683,發貨地:寶山區蕰川公路777號寶鋼廠區607-609室發貨到江蘇省 徐州市 云龍區、賈汪區、泉山區、銅山區、豐縣、沛縣、睢寧縣、新沂市、邳州市,以下是無取向電工鋼板50WW250磁感值的詳細頁面。 江蘇省,徐州市 原始社會末期,帝堯時彭祖建大彭氏國,是江蘇境內早出現的城邑。徐州歷史上為華夏九州之一,自古便是北國鎖鑰、南國門戶、兵家必爭之地和商賈云集中心,也是淮海地區的政治、經濟、文化中心。徐州有超過6000年的文明史和2600年的建城史,是帝王之鄉,有“九朝帝王徐州籍”之說。徐州是兩漢文化的發源地,有“彭祖故國、劉邦故里、項羽故都”之稱,因其擁有大量文化遺產、名勝古跡和深厚的歷史底蘊,也被稱作“東方雅典”。

無取向電工鋼板50WW250磁感值的詳細視頻已經上傳,我們的視頻將帶您領略產品的獨特設計、卓越品質以及出色性能,讓您對它有更深刻的認識和了解。

以下是:無取向電工鋼板50WW250磁感值的圖文介紹

電工鋼硅鋼片電工鋼亦稱硅鋼片,是電力、江蘇徐州本地電子和軍事工業不可缺少的金屬材料,亦是產量 的功能性材料,主要用作各種電機、江蘇徐州本地發電機和變壓器的鐵芯。(電工鋼簡介)既然是功能性材料,其性能檢測也是圍繞“功能”展開,這些指標在貿易和加工過程中會被經常提到,有一個簡略的認識能幫助大家更好地開展工作。電工鋼性能檢測主要分為以下幾個方面:磁性檢驗、江蘇徐州本地疊裝系數檢驗、江蘇徐州本地涂層附著性檢驗、江蘇徐州本地反復彎曲檢驗、江蘇徐州本地尺寸形狀表面檢驗和常規力學性能檢驗等電工鋼除上表品種類別外,還有一些特殊用途的電工鋼板,如0.15和0.20mm厚3%Si冷軋無取向硅鋼薄帶和0.025、江蘇徐州本地0.05及0.1mm厚3%Si冷軋取向硅鋼薄帶,用作中、江蘇徐州本地高頻電機和變壓器以及脈沖變壓器等;繼電器和電力開關用的0.7mm厚3%Si高強度冷軋無取向硅鋼板;新型高轉速電機轉子用的高強度冷軋電工鋼板;醫用核磁共振斷層掃描儀等磁屏蔽和高能加速器電磁鐵用的低碳電工鋼熱軋厚板和冷軋板;高頻電機和變壓器以及磁屏蔽用的4.5%~6.5%Si高硅鋼板等。

電工鋼硅鋼片Electrical steel, also known as silicon steel sheet, is an indispensable metal material in the power, electronics, and military industries, and is also the largest functional material in production. It is mainly used as the iron core for various motors, generators, and transformers. Since it is a functional material, its performance testing also revolves around "function". These indicators are often mentioned in trade and processing processes, and a brief understanding can help everyone better carry out their work. The performance testing of electrical steel mainly includes the following aspects: magnetic inspection, stacking coefficient inspection, coating adhesion inspection, repeated bending inspection, size and shape surface inspection, and conventional mechanical property inspection. In addition to the types of products listed above, there are also some special purpose electrical steel plates, such as 0.15 and 0.20mm thick 3% Si cold-rolled non oriented silicon steel strips and 0.025, 0.05, and 0.1mm thick 3% Si cold-rolled oriented silicon steel strips, which are used as intermediate and intermediate grade High frequency motors and transformers, as well as pulse transformers, etc; 0.7mm thick 3% Si high-strength cold-rolled non oriented silicon steel plate for relays and power switches; High strength cold-rolled electrical steel plate for new high-speed motor rotors; Low carbon electrical steel hot-rolled thick and cold-rolled plates for magnetic shielding and high-energy accelerator electromagnets such as medical magnetic resonance tomography scanners; 4.5% to 6.5% Si high silicon steel plates for high-frequency motors, transformers, and magnetic shielding.

Generally, motors, transformers, and other electrical components are required to have high efficiency, low power consumption, small size, and light weight. Electrical steel plates are usually guaranteed to have magnetic properties based on core loss and magnetic induction strength. Magnetic induction strength is the number of magnetic lines passing through a unit cross-sectional area of the iron core, also known as magnetic flux density. It represents the material‘s magnetization ability, measured in T. The magnetic induction strength of electrical steel plates is high, and the excitation current (also known as no-load current) of the iron core is reduced. Copper and iron losses are also reduced, which can save electrical energy. When the power of the motor and transformer remains constant, the magnetic induction intensity is high, and the design Bm can be increased. The cross-sectional area of the iron core can be reduced, which reduces the volume and weight of the iron core, and saves the amount of electrical steel plates, wires, insulation materials, and structural materials used. This can reduce the total loss and manufacturing cost of the motor and transformer, and is beneficial for the manufacturing, installation, and transportation of large transformers and motors. The main requirements for the performance of silicon steel are:

1. Low iron loss is the most important indicator of the quality of silicon steel sheets. Various countries classify grades based on iron loss values, with the lower the iron loss, the higher the grade.

2. Under strong magnetic fields, the magnetic induction intensity (magnetic induction) is high, which reduces the volume and weight of the iron core of the motor and transformer, saving silicon steel sheets, copper wires, and insulation materials.

3. The surface is smooth, flat, and the thickness is uniform, which can improve the filling coefficient of the iron core.

4. Good lamination performance is more important for manufacturing micro and small electric motors.

5. The adhesion and weldability of the surface insulation film are good, which can prevent corrosion and improve the punching performan

鹿程國際貿易有限公司成立以來,以“讓鹿程國際貿易有限公司走向世界”為目標,堅持“實用、耐用、節能、”的生產理念,不斷引進國內外技術,致力于 江蘇徐州汽車車輪用鋼的研發和制造。

電工鋼硅鋼片近20年來,我國硅鋼產業取得了長足的進步,這其中以首鋼、江蘇徐州當地武鋼和寶鋼為代表。得益于我國鋼鐵行業全流程的技術進步,這些企業在控制無取向硅鋼整體質量穩定性和取向硅鋼方面已經具有較高技術實力。2014年我國硅鋼生產達到823萬噸,高端產品有20~30萬噸的進口量,2015年,我國共生產電工鋼約836萬噸,進口量進一步下降到14萬噸。但是,與日本相比我國在高端電工鋼領域仍有不小的差距,這集中體現在高磁感無取向硅鋼、江蘇徐州當地超低鐵損Hi-B取向硅鋼和高硅鋼等產品上。例如,新日鐵公司(現新日鐵住金)能夠實現0.15~0.35mm系列厚度規格極低鐵損Hi-B取向電工鋼的穩定供貨,引領取向硅鋼工藝發展。在特殊用途硅鋼方面,日本鋼管公司(現JFE)通過氣相沉積法(CVD)滲硅的方式實現了高硅鋼薄帶的供貨。隨著我國裝備制造業的產業升級,高端硅鋼產品的需求會越來越迫切。我國與日韓等鋼鐵強國在這一領域的競爭將會更加激烈,這就要求我國相關科研人員通過革命性創新進行下一代硅鋼生產技術的研發,引領世界電工鋼技術的發展。低鐵損、江蘇徐州當地高磁感電機用無取向硅鋼、江蘇徐州當地薄規格超低鐵損高磁感取向硅鋼和中高頻節能電器用高硅鋼是電工鋼產業的發展方向。

在江蘇省徐州市采購無取向電工鋼板50WW250磁感值請認準鹿程國際貿易有限公司,品質保證讓您買得放心,用得安心,廠家直銷,減少中間環節,讓您購買到更加實惠、更加可靠的產品。(聯系人:鹿丙偉-13764370568,QQ:871956683,地址:寶山區蕰川公路777號寶鋼廠區607-609室)。