我們的電工鋼牌號詢問報價視頻現已上線,從細節到整體,從外觀到性能,讓您了解它的每一個方面。

以下是:電工鋼牌號詢問報價的圖文介紹

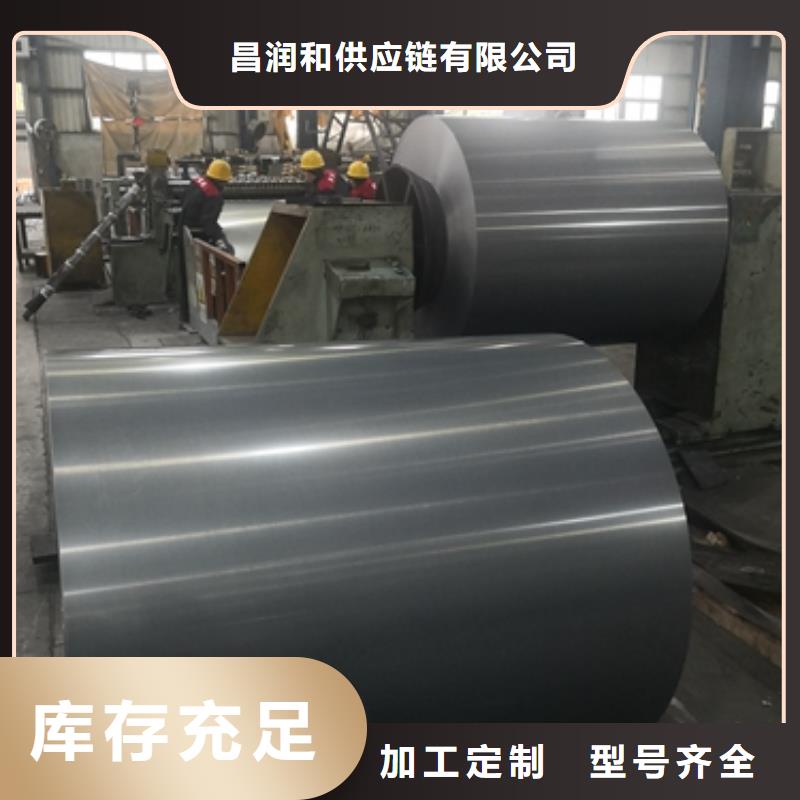

鹿程國際貿易有限公司位于寶山區蕰川公路777號寶鋼廠區607-609室,地理位置優越,交通便利。鹿程國際貿易有限公司是一家以 四川瀘州汽車車輪用鋼生產、銷售及安裝為一體的企業。公司自成立以來,堅持以“顧客滿意”為宗旨,以“不斷”為經營理念,以“科學管理”為手段。以“信譽至上”為基本原則。鹿程國際貿易有限公司在生產 四川瀘州汽車車輪用鋼深受廣大客戶的贊揚,具有良好的信譽。企業目標:質量,立業之本,管理,強業之路;效益,興業之源。今日的質量,明日的市場。 以科技為動力,以質量求生存。 以質量求生存,以質量求發展,向質量要效益。 效益來源于服務社會的回報。

電工鋼硅鋼片本文件按照 GB/T 1.1—2020《標準化工作導則 部分:標準化文件的結構和起草規則》的規定起草。本文件代替 Q/BQB 485-2020。本文件與 Q/BQB 485-2020 相比,主要修改內容如下:— 新增了普通型 Q、四川瀘州附近高磁極化強度型 QG、四川瀘州附近磁疇細化型 RK 產品牌號;— 補充配電變壓器專用和耐熱刻痕磁疇細化兩個類型產品;— 補充 B18P070、四川瀘州附近B20P075、四川瀘州附近B23P080、四川瀘州附近B27P085、四川瀘州附近B27P120、四川瀘州附近B30P090 六個高磁極化強度型產品和B18R055、四川瀘州附近B18R060、四川瀘州附近B20R060、四川瀘州附近B20R065、四川瀘州附近B23R070 五個磁疇細化型產品;— 依據 IEC 文件(IEC 6040-8-7 Edition 5.0 2020-09),對單片法(SST)磁性能檢測數據轉換規則進行調整;— 補充無 Cr 環保涂層產品相關規定;— 修改了鋼帶的浪高標準。請注意本文件的某些內容可能涉及 。本文件的發布機構不承擔識別 的責任。本文件由寶山鋼鐵股份有限公司硅鋼事業部和制造管理部提出。本文件由寶山鋼鐵股份有限公司硅鋼事業部、四川瀘州附近制造管理部和武鋼有限聯合起草。本文件所代替的歷次版本發布情況為:Q/BQB 485-2007,Q/BQB 485-2014,Q/BQB 485-2016,Q/BQB485-2018,Q/BQB 485-2020。

電工鋼硅鋼片硅鋼是一種硅鐵合金。用硅鋼軋制的片材是電工領域中應用廣的軟磁材料,因而硅鋼片又稱電工鋼片。硅鋼片廣泛用于電動機、發電機、變壓器、扼流圈、電磁機構、繼電器及測量儀表中電機工業大量使用厚度為0.35~0.50mm的硅鋼片,用于:中型旋轉機,壓縮電機,通用馬達,小型精密電機,電動汽車,壓縮機,通用電機,電源變壓器,精密變壓器,節能電機,焊機變壓器,穩壓器,磁性密封器,加速器用電磁鐵,汽車電機等;在電信高頻技術中常用0.05~0.20mm的薄帶鋼片,以便更有效地降低渦流損耗。熱軋硅鋼片厚度為0.35~0.50mm,密度為7.55~7.70g/cm3,多用于大、中、小型交、直流電動機;冷軋無取向硅鋼片厚度為0.35~0.50mm,密度為7.65~7.75g/cm3,多用于大型交流發電機、電動機,大、中、小型交、直流電動機;冷軋取向硅鋼片厚度為0.23mm 0.27mm 0.3mm 0.35mm,密度為7.65g/cm3,多用于電力變壓器、油浸式變壓器,干式變壓器,電抗器、磁放大器等;冷軋取向薄帶厚度為0.05~0.20mm,多用于無線電高頻變壓器。

電工鋼硅鋼片我國太原鋼鐵廠于1952年首先試制熱軋低硅鋼板(1%~2%Si),1954年正式生產。1957年由鋼鐵研究總院研制成功3%Si冷軋取向硅鋼,到1973年我國已掌握Armco技術 要點,鞍鋼進行試制但未能生產。1974年武漢鋼鐵公司從日本新日鐵引進冷軋取向硅鋼制造裝備和 。1976~1977年,鋼鐵研究總院在驗證和消化日本 的基礎上開發了Hi-B取向硅鋼。1979年武鋼正式生產取向硅鋼,到目前為止武鋼仍是我國取向硅鋼的主要生產基地。

電工鋼硅鋼片In addition to the types listed above, there are also some special purpose electrical steel plates, such as 0.15 and 0.20mm thick 3% Si cold-rolled non oriented silicon steel strips and 0.025, 0.05, and 0.1mm thick 3% Si cold-rolled oriented silicon steel strips, used for medium and high-frequency motors, transformers, and pulse transformers; 0.7mm thick 3% Si high-strength cold-rolled non oriented silicon steel plate for relays and power switches; High strength cold-rolled electrical steel plate for new high-speed motor rotors; Low carbon electrical steel hot-rolled thick and cold-rolled plates for magnetic shielding and high-energy accelerator electromagnets such as medical magnetic resonance tomography scanners; 4.5% to 6.5% Si high silicon steel plates for high-frequency motors, transformers, and magnetic shielding.Generally, motors, transformers, and other electrical components are required to have high efficiency, low power consumption, small size, and light weight. Electrical steel plates are usually guaranteed to have magnetic properties based on core loss and magnetic induction strength [1] [2]. The requirements for the performance of electrical steel plates are as follows:Low core loss (PT)Iron core loss refers to the ineffective electrical energy consumed by an iron core when magnetized in an alternating magnetic field of ≥ 50Hz, abbreviated as iron loss, also known as alternating loss, and its unit is W/kg. The ineffective electrical energy consumed due to various obstacles caused by magnetic flux changes not only loses electrical energy through the heating of the iron core, but also causes temperature rise of the motor and transformer. The iron loss (PT) of electrical steel includes three parts: hysteresis loss, eddy current loss (Pe), and anomalous loss (Pa). Electrical steel plates have low iron loss, which can save a lot of electricity, prolong the operating time of motors and transformers, and simplify cooling devices. Due to the iron loss of electrical steel plates, which accounts for 2.5% to 4.5% of the annual electricity generation in various countries, countries always try their best to reduce iron loss in the production of electrical steel plates, and use iron loss as the most important indicator to assess the magnetic properties of products. The iron loss value of products is used as the basis for classifying product grades. Cold rolled oriented electrical steel: Cold rolled oriented electrical steel is a high-end product in the field of electrical steel. Compared with cold rolled non oriented electrical steel, its magnetism has strong directionality; It has superior high magnetic permeability and low loss characteristics in the direction of easy magnetization rolling. The iron loss of oriented steel strip in the rolling direction is only 1/3 of that in the transverse direction, and the ratio of magnetic permeability is 6:1. Application: The main purpose of cold-rolled oriented silicon steel strip is for transformer manufacturing.Full process cold rolled non oriented silicon steel coating: The surface of the full process cold rolled silicon steel is coated with a semi transparent insulation coating, which has different codes in different standards. Taking Baosteel‘s Q/BQB 480 2014 as an example: