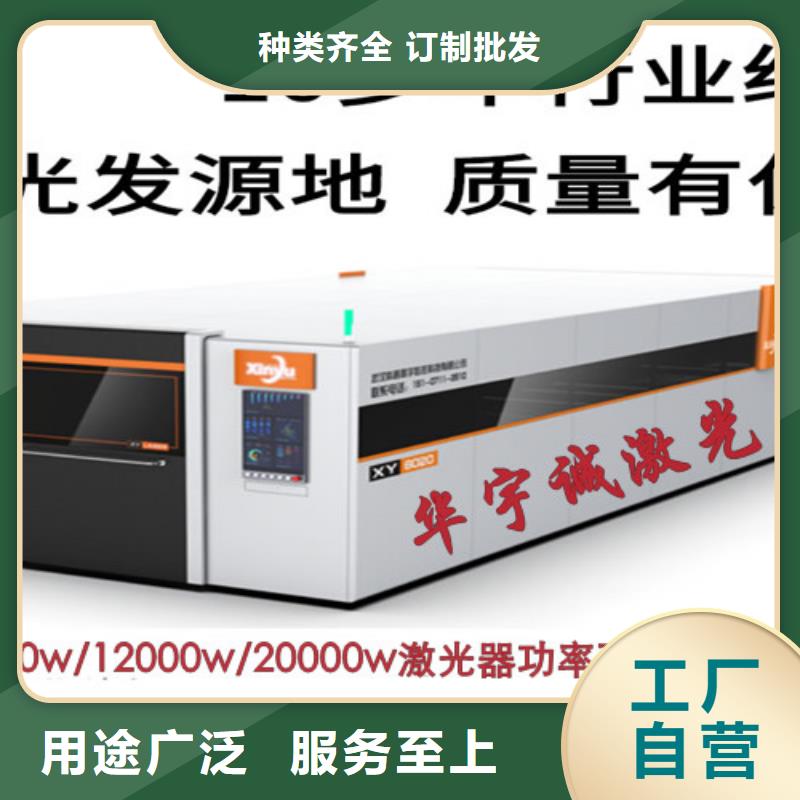

想要更直觀地了解光纖激光切割機-光纖激光切割機產品細節產品的細節和特色?我們為您制作了視頻,它將帶您進入一個比文字更加鮮活的世界。

以下是:光纖激光切割機-光纖激光切割機產品細節的圖文介紹

很多企業在使用光纖激光切割機時不注意機器的保養,導致設備壽命大幅縮短,那么光纖激光切割機該如何使用和保養?在使用光纖激光切割機機對物件進行加工的時候,需要學習光纖激光切割機設備使用、維護技巧,才能更好的發揮設備的功效,*大程度的提高設備的工作效率。

光纖激光切割機使用以及保養方法:

1)經常檢查鋼帶,一定保證拉緊。不然在運行中出了問題,有可能就會傷到人,嚴重還能導致人員死亡。鋼帶看似小東西,出了問題還是有點嚴重的。

2)每六個月檢查軌道的直線度及機器的垂直度,發現不正常及時維護調試。沒有做這個的,有可能切割出來的效果就不怎么好,誤差會增加,影響切割質量。這個是重中之重。

3)每周一次用真空吸塵器吸掉機器內的粉塵和污物,所有電器柜應關嚴防塵。

4)各導軌應經常清理,排除粉塵等雜物,保證設備正常齒條要經常擦拭,加潤滑油,保證潤滑而無雜物。導軌要經常進行清理和上潤滑油,還有就是電機也要經常的進行清理和上潤滑油,機器在行進中就能更好的走位,更準確的切割,切割出來的產品質量就會提高。

5)雙焦距激光切割頭是激光切割機上的易損物品,長期使用,導致激光切割頭損壞。

光纖激光切割機需要定期的進行檢查維修。如有變形或其他形態出現,這時候你就應該知道激光切割頭已經有點損壞了,要進行更換。不進行更換會影響切割質量,增加成本,有的產品可能還要進行二次加工,降低生產效率。

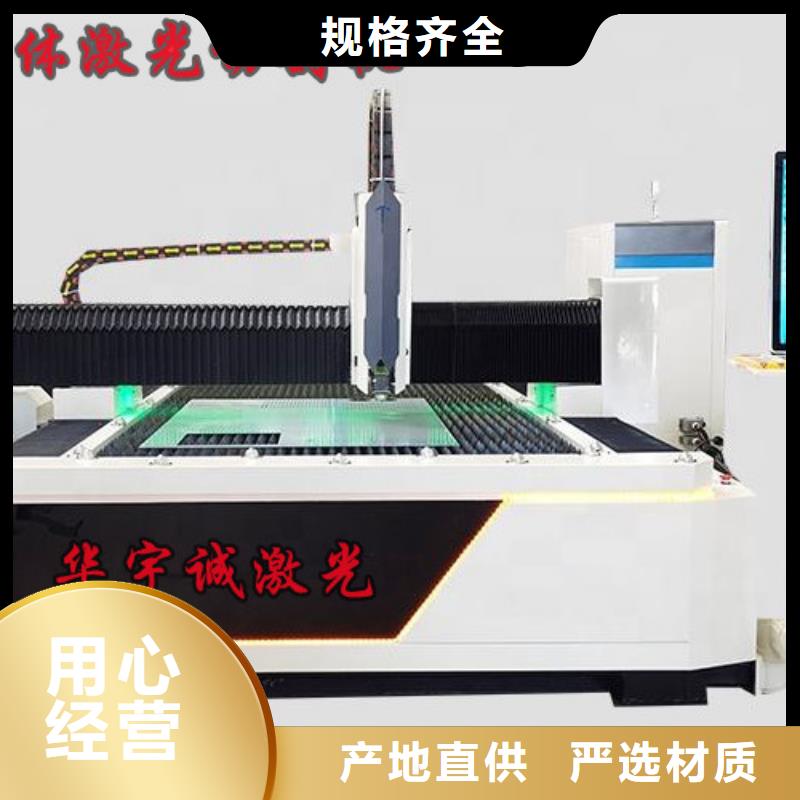

光纖激光切割機應用原理。光纖激光切割機選用較高能激光,根據光纖線導光器將激光傳送到激光頭,完成金屬復合材料的細致激光切割。和傳統機械設備切割技術對比,光纖激光切割機具有更好的激光切割效率和效果。

Xiner takes you to understand the application principles of fiber laser cutting machines. The fiber laser cutting machine uses high-energy lasers and transmits the laser to the laser head based on the fiber optic line guide, completing detailed laser cutting of metal composite materials. Compared with traditional mechanical equipment cutting technology, fiber laser cutting machines have better laser cutting efficiency and effectiveness.

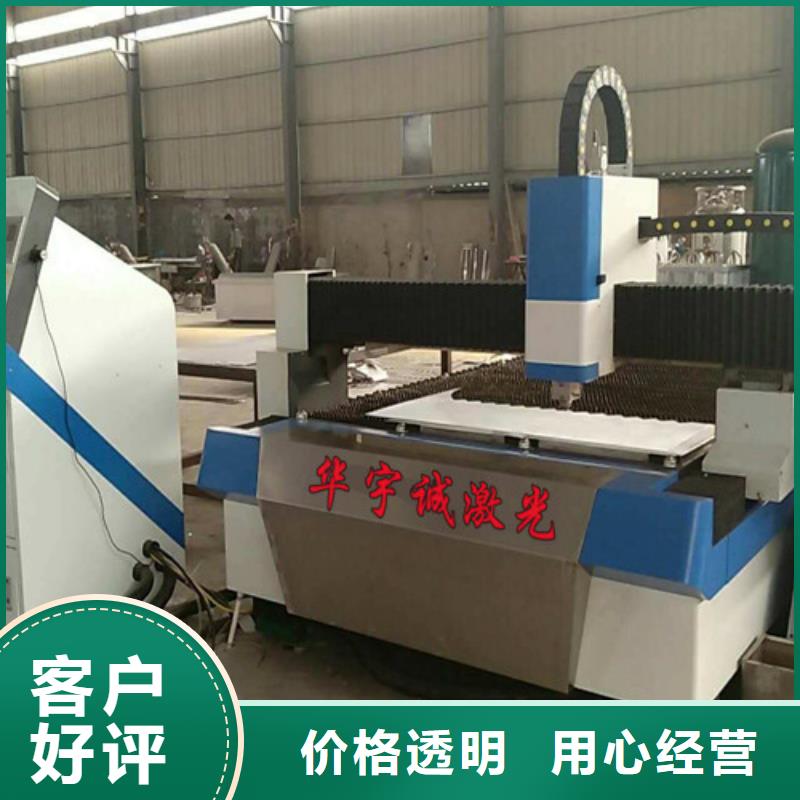

光纖切割機

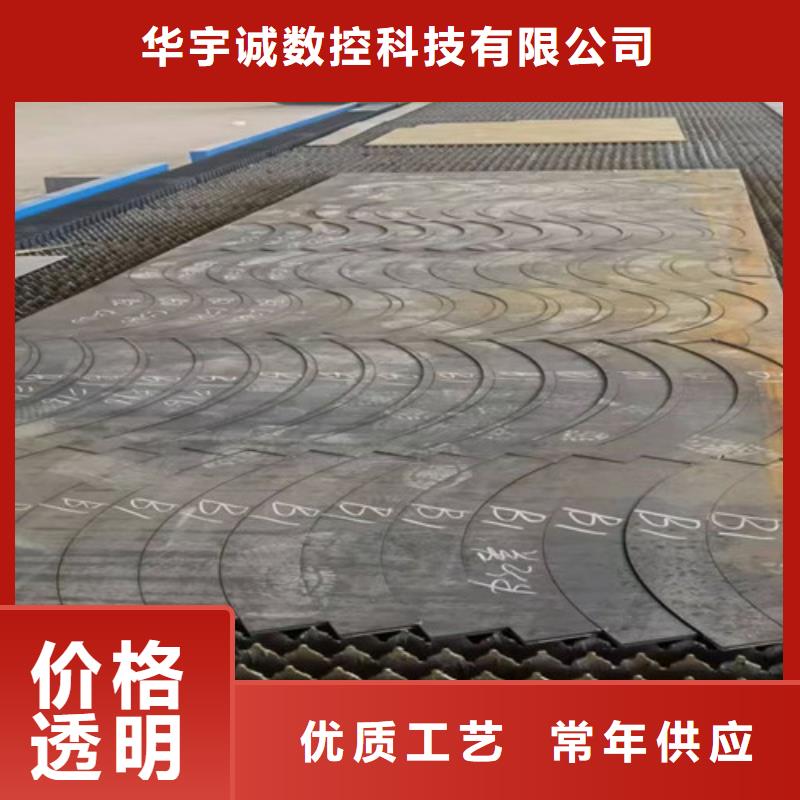

光纖激光切割機清晰地激光切割各種各樣金屬復合材料,如不銹鋼板、碳素鋼、鋁、銅等,同時還可以激光切割各種復雜的形態和曲線圖,如環形、正方形、五角星、人物肖像等。次之,在分割環節中,不用觸碰材料表面,因而也不會對材料表面產生任何損害,也能獲得更平滑的激光切割邊沿。

The optical fiber laser cutter can clearly laser cut various metal composite materials, such as stainless steel plate, carbon steel, aluminum, copper, etc., and can also laser cut various complex shapes and curves, such as rings, squares, pentagram, portraits, etc. Secondly, in the segmentation process, there is no need to touch the material surface, so there is no damage to the material surface and smoother laser cutting edges can be obtained.

光纖激光切割機能夠快速激光切割,大大節省了生產加工周期時間,了鈑金加工廠效率。

The fiber laser cutting machine can quickly laser cut, greatly saving production and processing cycle time, and improving the efficiency of sheet metal processing plants.

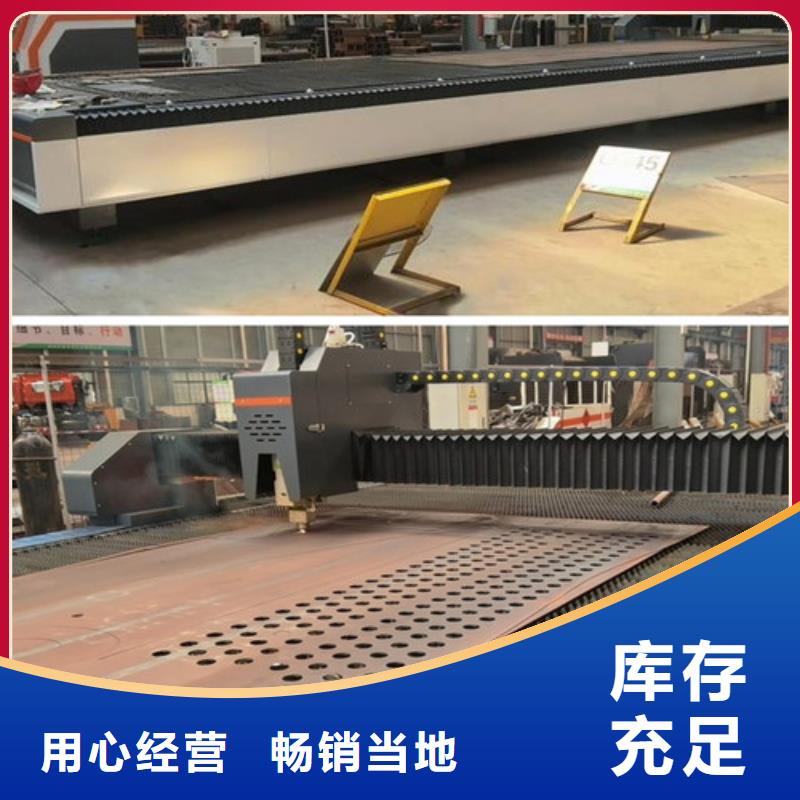

光纖激光切割機除開高質量激光切割外,還具備高密、性能穩定的特征。采用先進磁性和電子光學自動控制系統,可以實現高準激光切割,裝配精度為0.05mm,重復精度低于0.03mm,可以滿足工業制造業高精度規定。與此同時,光纖激光切割機機器設備結構簡單,抗震等級抗干擾性高,激光切割環節中不會受到外界影響,激光切割性能穩定。

In addition to high-quality laser cutting, fiber laser cutting machines also have the characteristics of high density and stable performance. Advanced magnetic and electron optics automatic control systems can be used to achieve high-precision laser cutting. The assembly accuracy is 0.05mm, and the repetition accuracy is less than 0.03mm, which can meet the high-precision requirements of industrial manufacturing. At the same time, the fiber laser cutting machine has a simple structure, high seismic resistance, and anti-interference ability. The laser cutting process is not affected by external factors, and the laser cutting performance is stable.

光纖切割機廠家

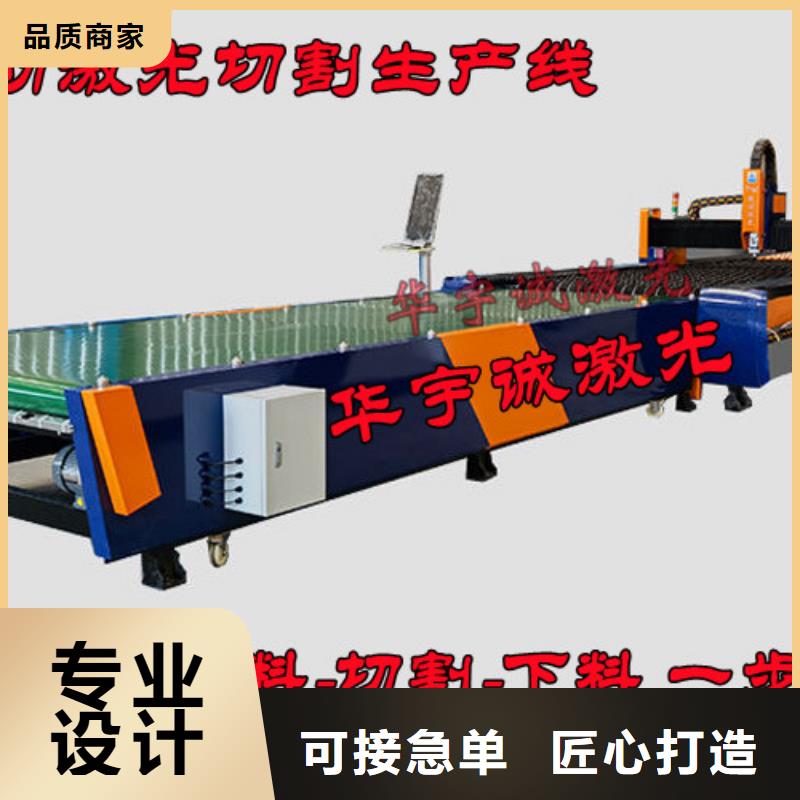

簡單點來說,光纖激光切割機是一種準確、相對穩定的金屬切割設備,具備各種各樣良好的特性,廣泛用于加工制造業。它不僅能提高工作效率,而且還能大幅度降低生產成本,也受到了加工制造業人員的熱捧。伴隨著技術發展

Simply put, fiber laser cutting machines are an accurate and relatively stable metal cutting equipment with various good characteristics, widely used in the processing and manufacturing industry. It not only improves work efficiency, but also significantly reduces production costs, and is also highly sought after by processing and manufacturing personnel. Accompanied by technological development

華宇誠數控科技有限公司致力于 內蒙古呼和浩特大功率激光切割機領域的整體,聚焦于 內蒙古呼和浩特大功率激光切割機市場的深耕與拓展,以國際視野,全球整合的眼界與格局,把握前沿技術,鍛造保障能力,追求事業品質。愿與各位同道,各位朋友,各位有識之士共勷偉事,共迎美好明天。

你有鰭,這里是大海,你有翅,這里是藍天。