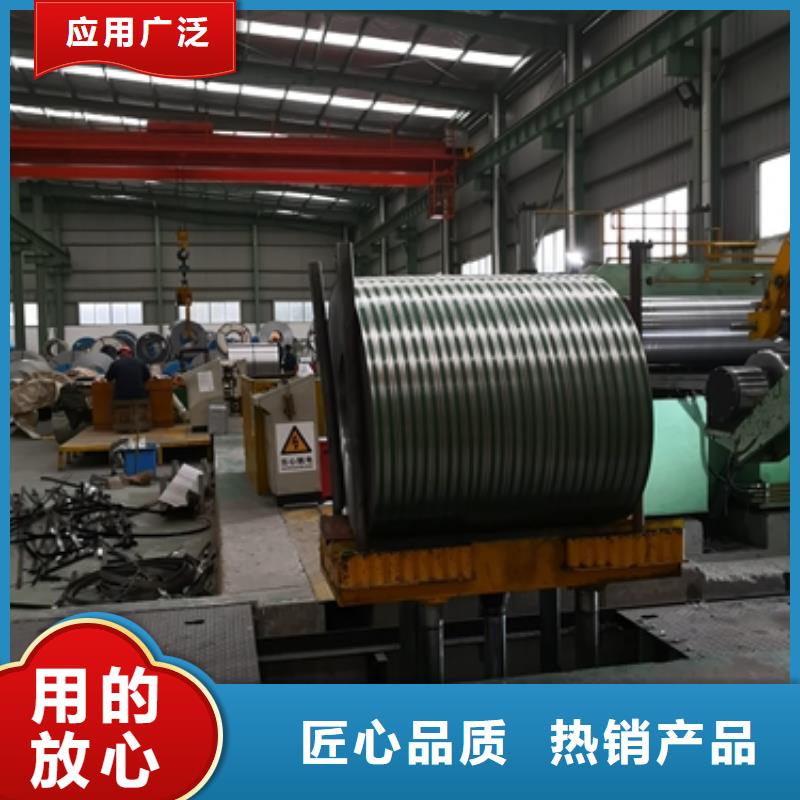

我們的寶鋼硅鋼出口18RK070視頻將帶您走進產品的生產線,讓您親眼見證產品的每一個制作環節和工藝細節。

以下是:寶鋼硅鋼出口18RK070的圖文介紹

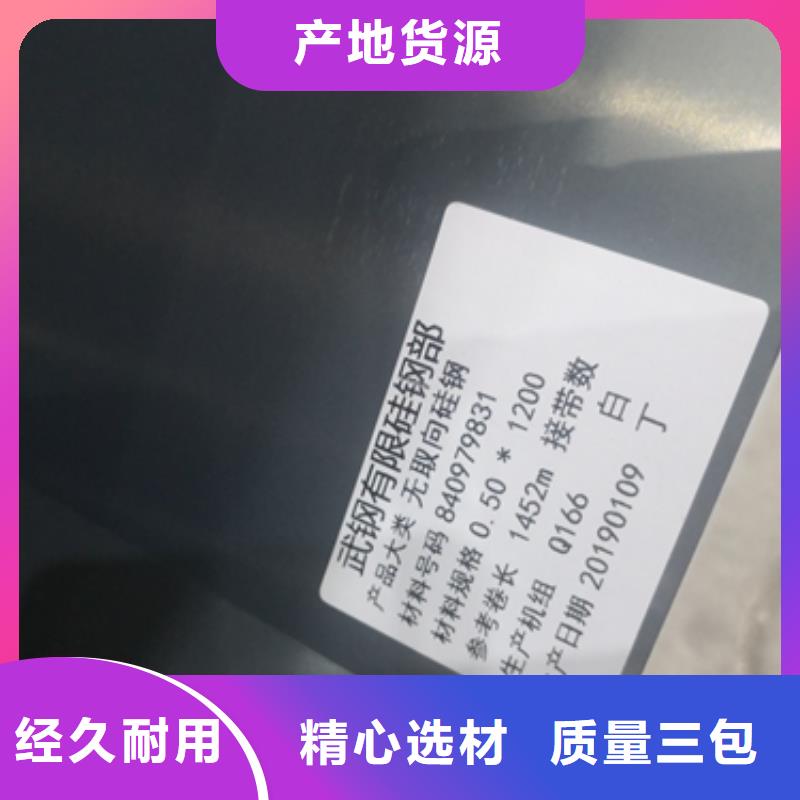

電工鋼硅鋼片硅鋼以鐵芯損耗(簡稱鐵損)和磁感應強度(簡稱磁感)作為產品磁性保證值。硅鋼鐵損低可節省大量電能,延長電機和變壓器工作運轉時間和簡化冷卻系統。由于硅鋼鐵損造成的電量損失占全年發電量的2.5%~4.5%,其中變壓器鐵損約占50%,1~100kW小型電機約占30%,日光燈鎮流器約占15%。硅鋼磁感高,鐵芯的激磁電流降低,也節省電能。硅鋼磁感高可使設計的 磁感(Bm)高、遼寧本溪本地鐵芯體積小、遼寧本溪本地重量輕,節省硅鋼、遼寧本溪本地導線、遼寧本溪本地絕緣材料和結構材料等,既使電機和變壓器損耗和制造成本降低,又便于組裝和運輸。由帶齒圓形沖片疊成鐵芯的電機在運轉狀態下工作。要求硅鋼板為磁各向同性,用無取向硅鋼制造。由條片疊成鐵芯或由條帶卷繞成鐵芯的變壓器在靜止狀態下工作,用磁各向異性大的冷軋取向硅鋼制造。此外,要求硅鋼具有好的沖剪性,表面光滑平整和厚度均勻,好的絕緣膜和磁時效小。

鹿程國際貿易有限公司主要生產銷售: 遼寧本溪汽車車輪用鋼。我司憑借優良的管理、開發優勢,借助超前的開發理念、先進的發展思想以及成功的運作模式,公司的規模也不斷地發展.公司不斷進取,加快加強項目開發運作,進一步完善開發機制,打造公司的品牌效應。用戶至上,以用戶為中心”是公司永遠堅持的服務宗旨,贏得用戶的贊許是我們的榮譽,及時滿足用戶的需求,是我們公司的愿望。長期以來,公司員工以優質的服務,取悅于用戶,以誠信的言行取信于用戶,得到了用戶們的好評。我們期待著與您更加愉快的合作!公司的發展,離不開社會的大力支持,在社會的支持和幫助下,我們正昂首闊步邁向未來!我們,將繼往開來,創造出更加美好、燦爛的明天!

電工鋼硅鋼片:半有機無鉻極厚涂層J C5 C-5 EC-5-P C-6涂層通常以磷酸鹽、遼寧本溪硅酸鹽等無機成分為主,添加一定量的無機填料和有機成分,不含有鉻元素,杜絕了用戶退火、遼寧本溪發藍和使用過程中發生六價鉻含量超標的可能性,性、遼寧本溪環保性 。膜厚比 M 涂層更厚,絕緣性比 M 涂層顯著提高,沖片性也顯著提高,在中性氣氛或弱還原性爐子氣氛中,可承受的應力退火溫度一般可達 800℃,在退火時,層間電阻會有一定降低。涂層能承受 300-550℃的涂層燒除處理,可用于重建電機定子時,去除電機定子繞組的絕緣層,也可用于風冷式或油浸式。

電工鋼硅鋼片In addition to the types listed above, there are also some special purpose electrical steel plates, such as 0.15 and 0.20mm thick 3% Si cold-rolled non oriented silicon steel strips and 0.025, 0.05, and 0.1mm thick 3% Si cold-rolled oriented silicon steel strips, used for medium and high-frequency motors, transformers, and pulse transformers; 0.7mm thick 3% Si high-strength cold-rolled non oriented silicon steel plate for relays and power switches; High strength cold-rolled electrical steel plate for new high-speed motor rotors; Low carbon electrical steel hot-rolled thick and cold-rolled plates for magnetic shielding and high-energy accelerator electromagnets such as medical magnetic resonance tomography scanners; 4.5% to 6.5% Si high silicon steel plates for high-frequency motors, transformers, and magnetic shielding.Generally, motors, transformers, and other electrical components are required to have high efficiency, low power consumption, small size, and light weight. Electrical steel plates are usually guaranteed to have magnetic properties based on core loss and magnetic induction strength [1] [2]. The requirements for the performance of electrical steel plates are as follows:Low core loss (PT)Iron core loss refers to the ineffective electrical energy consumed by an iron core when magnetized in an alternating magnetic field of ≥ 50Hz, abbreviated as iron loss, also known as alternating loss, and its unit is W/kg. The ineffective electrical energy consumed due to various obstacles caused by magnetic flux changes not only loses electrical energy through the heating of the iron core, but also causes temperature rise of the motor and transformer. The iron loss (PT) of electrical steel includes three parts: hysteresis loss, eddy current loss (Pe), and anomalous loss (Pa). Electrical steel plates have low iron loss, which can save a lot of electricity, prolong the operating time of motors and transformers, and simplify cooling devices. Due to the iron loss of electrical steel plates, which accounts for 2.5% to 4.5% of the annual electricity generation in various countries, countries always try their best to reduce iron loss in the production of electrical steel plates, and use iron loss as the most important indicator to assess the magnetic properties of products. The iron loss value of products is used as the basis for classifying product grades. Cold rolled oriented electrical steel: Cold rolled oriented electrical steel is a high-end product in the field of electrical steel. Compared with cold rolled non oriented electrical steel, its magnetism has strong directionality; It has superior high magnetic permeability and low loss characteristics in the direction of easy magnetization rolling. The iron loss of oriented steel strip in the rolling direction is only 1/3 of that in the transverse direction, and the ratio of magnetic permeability is 6:1. Application: The main purpose of cold-rolled oriented silicon steel strip is for transformer manufacturing.Full process cold rolled non oriented silicon steel coating: The surface of the full process cold rolled silicon steel is coated with a semi transparent insulation coating, which has different codes in different standards. Taking Baosteel‘s Q/BQB 480 2014 as an example: