以下是:B50AH470推薦廠家的產品參數

| 產品參數 |

|---|

| 產品價格 | 2/噸 |

|---|

| 發貨期限 | 3天內 |

|---|

| 供貨總量 | 50000 |

|---|

| 運費說明 | 電議 |

|---|

| 最小起訂 | 1 |

|---|

| 質量等級 | 精品 |

|---|

| 是否廠家 | 是 |

|---|

| 產品材質 | 冷軋 |

|---|

| 產品品牌 | 寶武日本進口 |

|---|

| 產品規格 | 0.08-0.65 |

|---|

| 發貨城市 | 上海武漢 |

|---|

| 產品產地 | 上海武漢 |

|---|

| 加工定制 | 粗加工 |

|---|

| 產品型號 | 多種 |

|---|

| 可售賣地 | 全國 |

|---|

| 質保時間 | 一年 |

|---|

| 適用領域 | 電器馬達電機變壓器磁感器互感器穩壓器繼電器電磁開關新能源電機電動汽車變壓器軍工電機發電機組航天造船汽車等 |

|---|

| 是否進口 | 否 |

|---|

| 品名 | 電工鋼 冷軋無取向電工鋼 冷軋取向電工鋼卷冷軋取向硅鋼 取向電工鋼冷軋無取向硅鋼冷軋無取向硅鋼 |

|---|

| 規格 | 0.08 0.1 0.05 0.18 0.2 0.23 0.27 0.3 0.35 0.5 0.65 1.0mm |

|---|

| 包裝 | 原廠精包裝 |

|---|

| 用途 | 電器馬達電機變壓器磁感器互感器穩壓器繼電器電磁開關新能源電機電動汽車變壓器軍工電機發電機組航天造船汽車等 |

|---|

以下是:B50AH470推薦廠家的圖文視頻

【導語】:您是想要在四川省廣安市采購高質量的B50AH470廠家產品嗎?鹿程國際貿易有限公司是您的不二之選!我們致力于提供品質保證、價格優惠的B50AH470廠家產品,品種齊全,不斷創新,致力于滿足廣大客戶的多種需求,聯系人:鹿丙偉-13764370568,QQ:871956683,地址:《寶山區蕰川公路777號寶鋼廠區607-609室發貨到四川省 廣安市 岳池縣、武勝縣、鄰水縣、華鎣市》。 四川省,廣安市 廣安市,別稱賨州、賨城,四川省轄地級市,位于四川盆地東部,地處亞熱帶濕潤季風氣候區,四季分明,氣候溫暖,雨量充沛,物產豐富,境內嘉陵江、渠江曲折回環,華鎣山、銅鑼山、明月山平行分布于市境東部。總面積6339平方千米,全市下轄2個區、3個縣,代管1個縣級市。截至2022年末,廣安市常住人口323.8萬人。

【新品發布,視頻先行!】B50AH470廠家產品,等你來探!

以下是:B50AH470廠家的圖文介紹

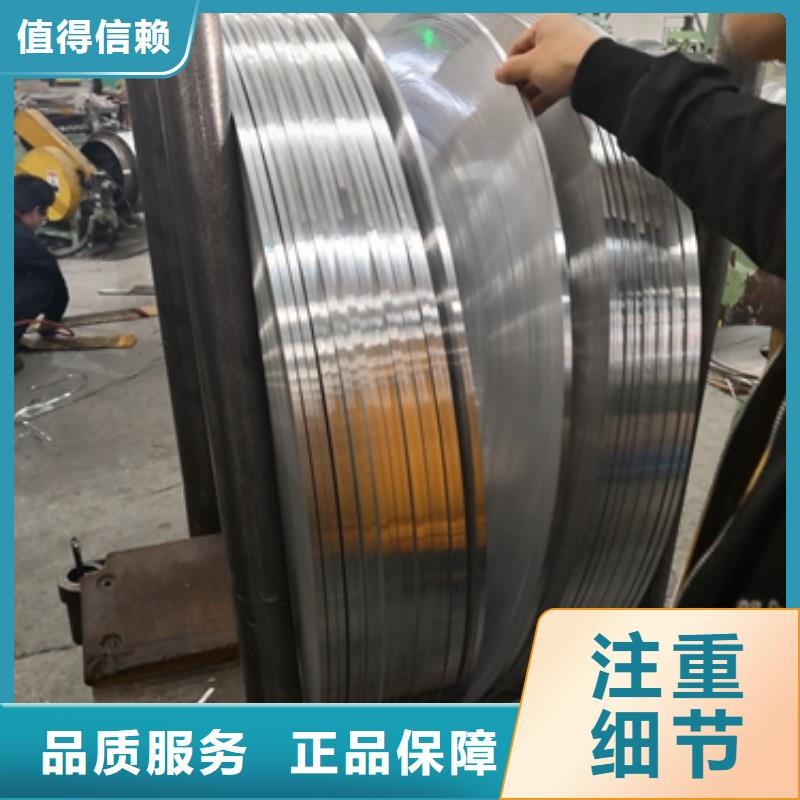

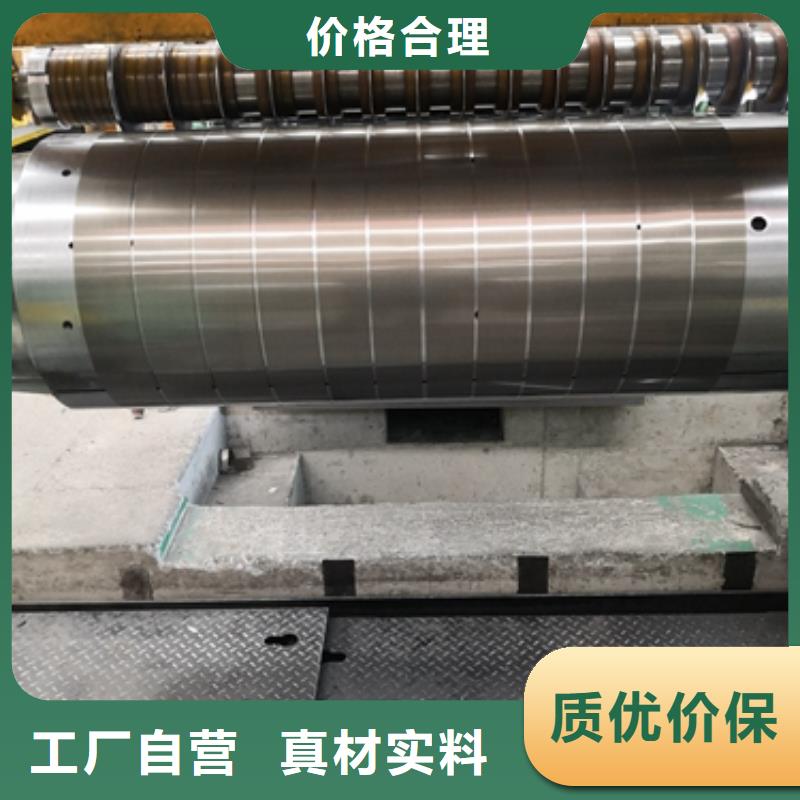

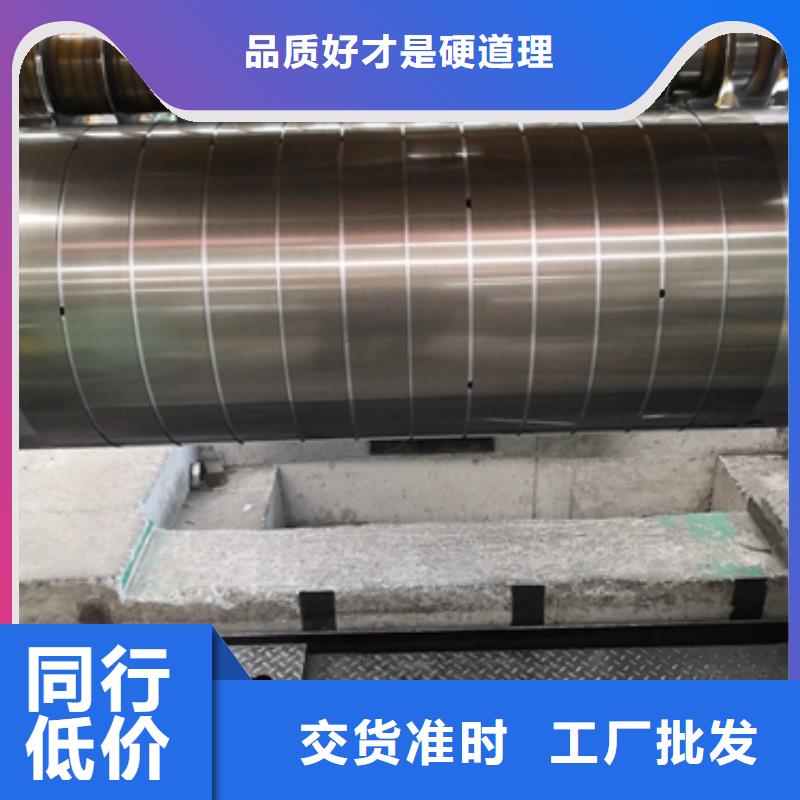

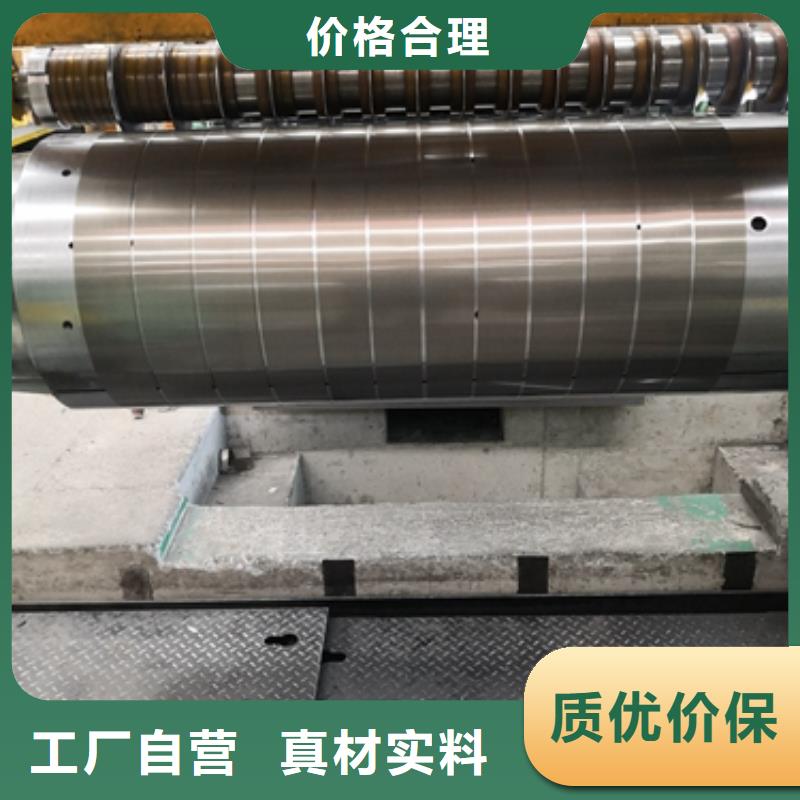

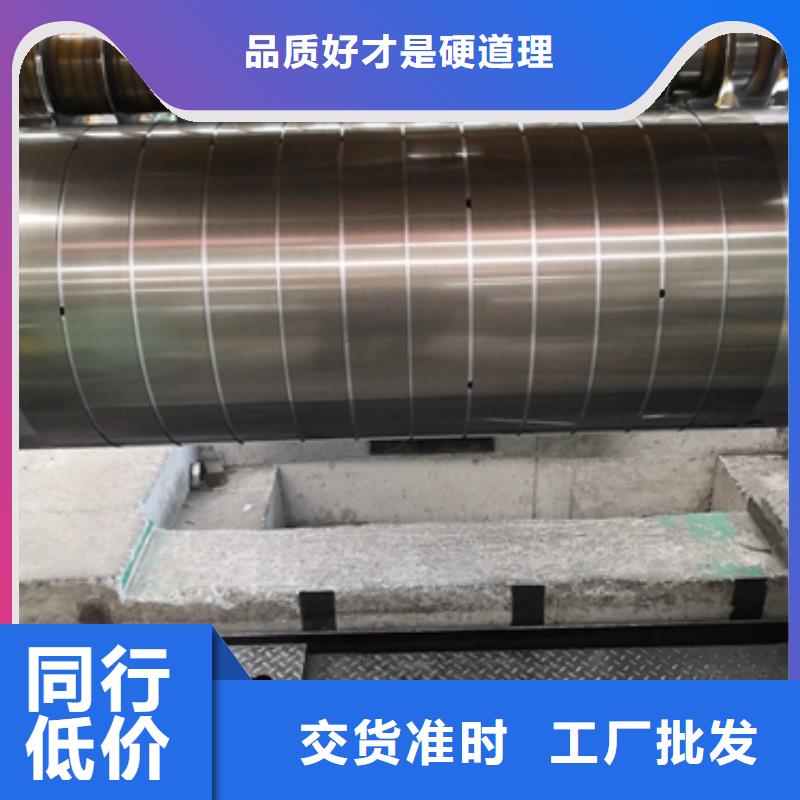

電工鋼硅鋼片硅鋼是一種硅鐵合金。用硅鋼軋制的片材是電工領域中應用廣的軟磁材料,因而硅鋼片又稱電工鋼片。硅鋼片廣泛用于電動機、發電機、變壓器、扼流圈、電磁機構、繼電器及測量儀表中電機工業大量使用厚度為0.35~0.50mm的硅鋼片,用于:中型旋轉機,壓縮電機,通用馬達,小型精密電機,電動汽車,壓縮機,通用電機,電源變壓器,精密變壓器,節能電機,焊機變壓器,穩壓器,磁性密封器,加速器用電磁鐵,汽車電機等;在電信高頻技術中常用0.05~0.20mm的薄帶鋼片,以便更有效地降低渦流損耗。熱軋硅鋼片厚度為0.35~0.50mm,密度為7.55~7.70g/cm3,多用于大、中、小型交、直流電動機;冷軋無取向硅鋼片厚度為0.35~0.50mm,密度為7.65~7.75g/cm3,多用于大型交流發電機、電動機,大、中、小型交、直流電動機;冷軋取向硅鋼片厚度為0.23mm 0.27mm 0.3mm 0.35mm,密度為7.65g/cm3,多用于電力變壓器、油浸式變壓器,干式變壓器,電抗器、磁放大器等;冷軋取向薄帶厚度為0.05~0.20mm,多用于無線電高頻變壓器。

電工鋼硅鋼片Intro of iron core of automobile driving motor。At present, the motor technology of high-speed punching of stator and rotor iron core at home and abroad has developed rapidly. With the development of stamping equipment, new equipment with high quality, high efficiency and high precision has been provided for the production of motor punching pieces of high-speed punching of stator and rotor iron core at home and abroad, which has brought the motor punching process technology. Therefore, the design technology of new technology and equipment suitable for it has become a new research topic. The simultaneous separation of stator punching groove and stator punching groove of motor high-speed punching stator rotor iron core the simultaneous cutting of air gap between rotor punching and rotor punching groove is a new technological scheme applied to high-speed punching machine. This scheme has been widely used in foreign countries and has just begun research and application in domestic motor industry. Therefore, some discussions are made to realize the design technology of this technology according to the required technological equipment.The influence of motor high-speed punching of stator and rotor iron core: the influence of motor punching process technology of motor high-speed punching of stator and rotor iron core in new product development the traditional process of motor punching in our country is two categories: double punching and single punching, which are analyzed as follows:1) the process scheme of double punching groove: this scheme has good groove shape and uniformity, few processes and few tooling, but the tooling is complex and requires high precision, good equipment conditions, long tooling manufacturing cycle and Cheng Bengao, which is only suitable for mass production and is not conducive to new product development and small batch trial production.2) single-type punching process scheme: this scheme has poor groove shape, many processes, many tooling, many equipments, simple tooling, unstable quality, long production cycle and Cheng Bengao, and is only suitable for medium and small batch production.Requirements for high-speed punching of stator and rotor iron core of motor: 1. Positioning accuracy requirements. In this technological scheme, the two composite processes of punching groove separation and punching groove cutting air gap require the same positioning Benchmark, ensuring that the concentricity of the groove shape of the stator and rotor, the outer circular dove tail groove and shaft hole is not more than 0.02mm, the positioning of the center hole meets the technical requirements of concentricity, and the joint positioning of the small side hole and the center hole meets the requirements of circumferential orientation. 2. Precision requirements of composite process. Punching and groove separation compound process: This process has Groove-shaped convex mold and incision convex mold to complete the progressive blanking process. This process first punches and then cuts to separate the fixed and rotor punching pieces. The Two convex molds act synchronously on the same center track, and the central included angle between the two convex molds is one and a half times the central included angle of the groove. This process equipment is applied to high-speed punching machines, the groove-shaped indexing accuracy is guaranteed by the CAM stepping mechanism on the equipment;Electric vehicle is an economical and clean green vehicle based on electric drive,Environment and other aspects have * competitiveness, and can conveniently use modern control technology to realize its electromechanical integration, with broad development prospects.The motor drive system of the iron core of the automobile drive motor is the power source of the electric vehicle, and is the main body and internal basis for determining various performance indexes of the automobile operation. At present, electric vehicle motors mainly include DC motors, induction motors, permanent magnet brushless motors and switched reluctance motors.Automobile drive motor iron core permanent magnet brushless motor can be divided into two categories: one is permanent magnet synchronous motor with sine wave current,The other is the BLDC motor with rectangular pulse wave current.Two kinds of motors, the rotor is magnet, the motor rotor does not need brush and excitation winding, through stator winding commutation to generate rotating torque. Because the rotor has no excitation winding, no copper consumption, small magnetic flux and very small iron consumption at low load, therefore, the permanent magnet brushless motor has a high "Power/mass" ratio and can run at high speed. At the same time, it is easy to cool down because there is no abrasion of the rotor and the stator winding is the main heat source.The characteristics of the iron core of the automobile driving motor; The permanent magnet brushless motor of the iron core of the automobile driving motor has high reliability and high output power. Compared with other motors with the same rotating speed, it has the characteristics of small volume, light weight, easy maintenance, high efficiency, high power factor, etc. The rotor has small electromagnetic time constant and good dynamic characteristics of the motor. Through adjustment and conduction angle, constant power operation can be realized, and the efficiency of the motor can also be optimized by optimizing control angle, thus obtaining wider constant power operation area and higher efficiency.Overview of motor high speed punching stator and rotor iron core

我廠采用先進的生產技術及科學管理制度,秉承誠信、保質、熱情的服務宗旨,深得廣大客戶的好評。鹿程國際貿易有限公司將一如既往的嚴格執行各項標準,不斷提高 四川廣安汽車車輪用鋼產品質量和服務,使我們的 四川廣安汽車車輪用鋼產品成為您的選擇,愿我們用優質的 四川廣安汽車車輪用鋼產品和真誠的服務與您建立長久友好的合作關系。真誠歡迎各新老客戶光臨洽談,攜手合作共創輝煌。

電工鋼硅鋼片本文件規定了公稱厚度為 0.18mm、四川廣安本地0.20mm、四川廣安本地0.23mm、四川廣安本地0.27mm、四川廣安本地0.30mm 和 0.35mm 全工藝冷軋取向電工鋼帶的定義、四川廣安本地分類和代號、四川廣安本地尺寸、四川廣安本地外形、四川廣安本地重量、四川廣安本地磁性能、四川廣安本地檢驗和試驗、四川廣安本地包裝、四川廣安本地標志及質量證明書等要求。本文件適用于寶山鋼鐵股份有限公司生產的以終退火狀態交貨的全工藝冷軋取向電工鋼帶(以下簡稱產品)。2 規范性引用文件下列文件中的內容通過文中的規范性引用而構成本文件必不可少的條款。其中,注日期的引用文件,僅該日期對應的版本適用于本文件;不注日期的引用文件,其 版本(包括所有的修改單)適用于本文件。GB/T 228.1 金屬材料拉伸試驗 部分:室溫實驗法GB/T 247 鋼板和鋼帶包裝、四川廣安本地標志及質量證明書的一般規定GB/T 2521.2 全工藝冷軋電工鋼 第 2 部分:晶粒取向鋼帶(片)GB/T 2522 電工鋼片(帶)表面絕緣電阻、四川廣安本地涂層附著性測試方法GB/T 2900.60 電工術語 電磁學GB/T 3655 用愛潑斯坦方圈測量電工鋼片(帶)磁性能的方法GB/T 4340.1 金屬材料維氏硬度試驗 部分:試驗方法GB/T 8170 數值修約規則與極限數值的表示和判定GB/T 9637 電工術語磁性 材料與元件GB/T 13789 用單片測試儀測量電工鋼片(帶)磁性能測量方法GB/T 17505 鋼及鋼產品 交貨一般技術要求GB/T 18253 鋼及鋼產品檢驗文件的類型GB/T 19289 電工鋼片(帶)的密度、四川廣安本地電阻率和疊裝系數的測量方法YB/T 4292 電工鋼帶(片)幾何特性測試方法Q/BQB 400 冷軋產品的包裝、四川廣安本地標志及檢驗文件IEC 60404-8-7Magnetic materialsSpecifications for individual materials – Cold-rolled grain-orientedelectrical steel strip and sheet delivered in the fully-processed stateIEC/TR 62581-2010 Methods of measurement of the magnetostriction characteristics by meansof single sheet and Epstein test specimens3 術語和定義GB/T 2521.2、四川廣安本地GB/T 2900.60、四川廣安本地GB/T 9637 和 YB/T 4292 界定的以及下列術語適用于本文件。

【總結】:今年在四川省廣安市購買B50AH470廠家有了新選擇,鹿程國際貿易有限公司始終堅守以用戶為中心的服務理念,將品質作為發展的基石。廠家直銷,確保為您提供價格實惠且品質卓越的B50AH470廠家產品。如需購買或咨詢,請隨時聯系我們,聯系人:鹿丙偉-13764370568,QQ:871956683,地址:寶山區蕰川公路777號寶鋼廠區607-609室。