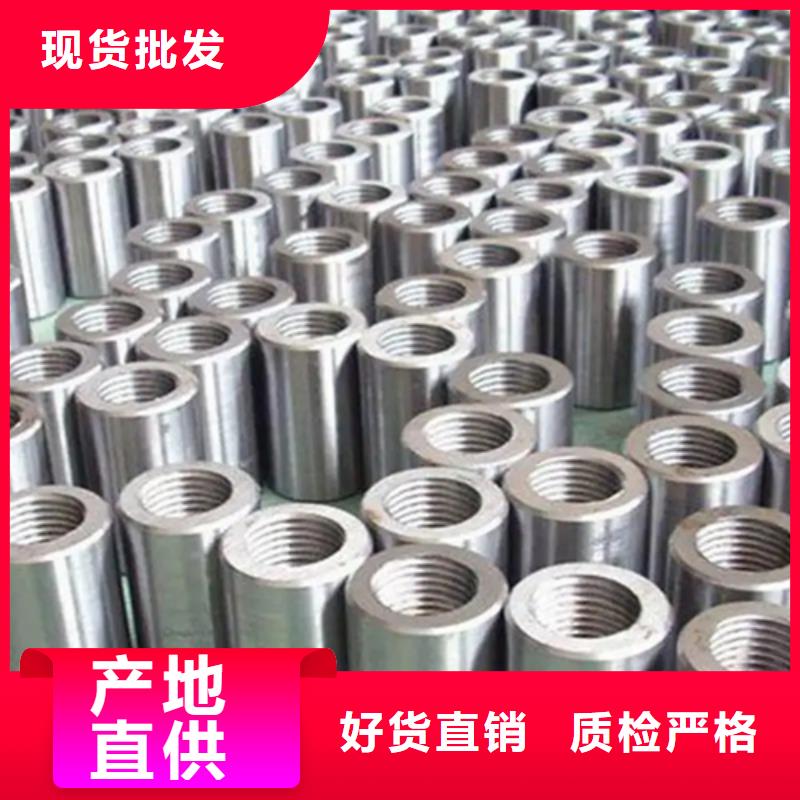

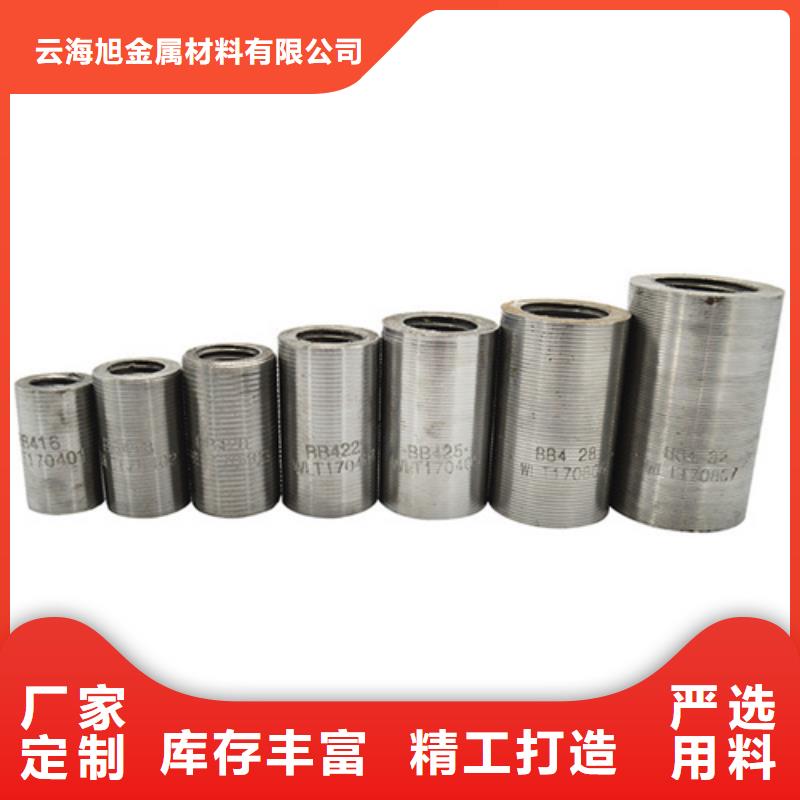

我們的實拍鋼筋套筒鋼筋套筒加工質量上乘視頻將為您呈現產品的真實面貌和卓越性能,讓您更好地了解產品的優點和特點,不容錯過!

以下是:鋼筋套筒鋼筋套筒加工質量上乘的圖文介紹

專注太原16的鋼筋套筒行業十余年

太原16的鋼筋套筒的詳細介紹

支持定制質量安心

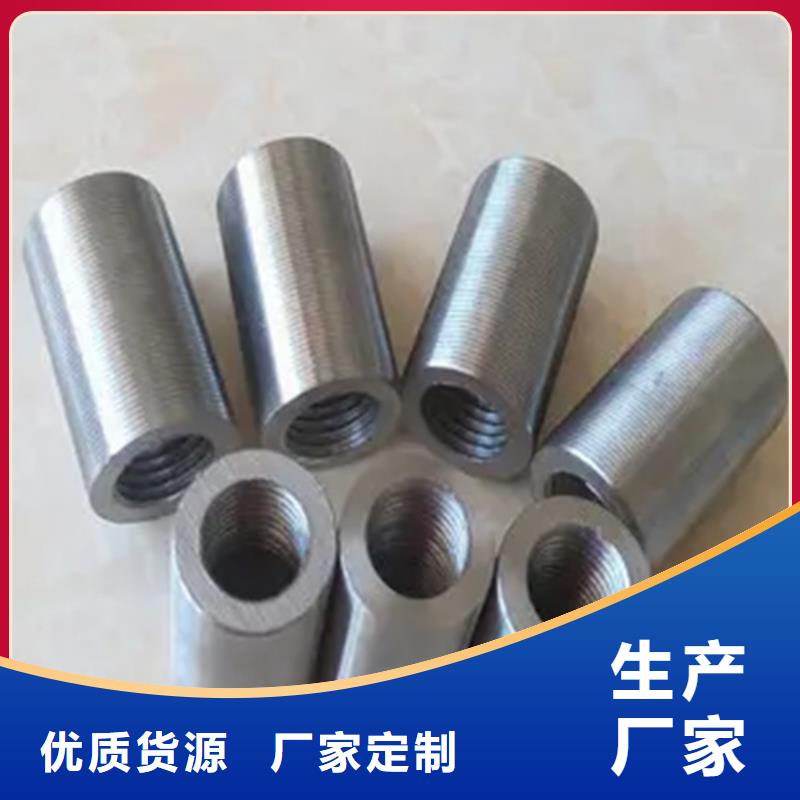

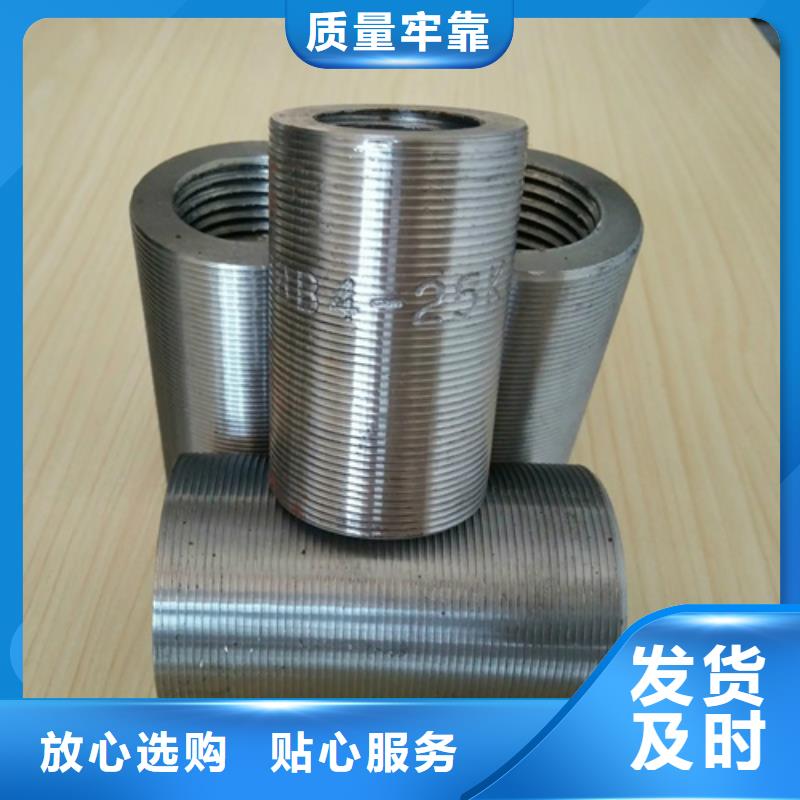

直螺紋鋼筋套筒連接套筒連接的七大原則:1.直螺紋鋼筋連接套筒接頭宜設置在受力較小處,在同一根鋼筋宜少設接頭。2.木行架和拱的拉桿(軸心受拉及小偏心受拉構件)不得采用綁扎搭接接頭。3.受拉鋼筋直徑大于28mm及受壓鋼筋直徑大于32mm時,不宜采用綁扎搭接接頭;4.搭接長度范圍內配制箍筋:直徑不應小于搭接鋼筋直徑的0.25倍鋼筋受拉時,箍筋間距不應大于搭接鋼筋較小直徑的5倍,且不應大于100mm鋼筋受壓時箍筋間距不應大于搭接鋼筋較小直徑的10倍,且不應大于200mm當受壓鋼筋直徑大于25mm時,應在搭接接頭兩個端面外100mm范圍內各設兩個箍筋。5.縱向受壓鋼筋搭接長度不應小于縱向受拉鋼筋搭接長度的0.7倍,且不應小于200mm。6需進行疲勞驗算的構件:縱向受拉鋼筋不得采用綁扎搭接接頭,不宜采用焊接接頭。7.直接承受吊車荷載的鋼筋混凝土吊車梁、屋面梁及屋架下弦的縱向受拉鋼筋必須采用焊接接頭時。

4大優勢值得信賴

多年行業經驗為您提供更好的太原16的鋼筋套筒購物體驗

YEARS OF INDUSTRY EXPERIENCE TO PROVIDE YOU WITH A BETTER SHOPPING EXPERIENCE

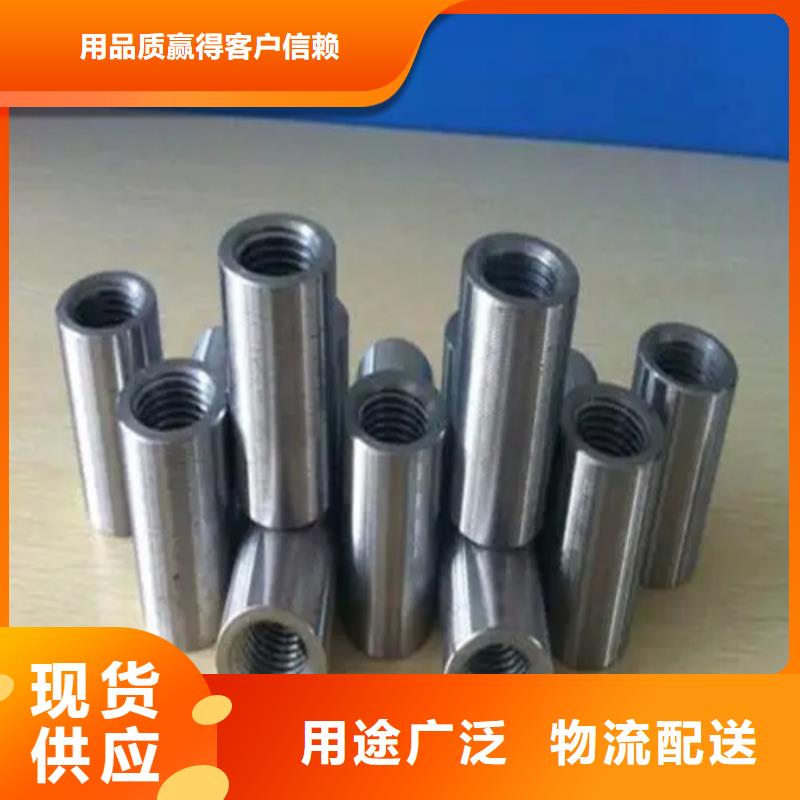

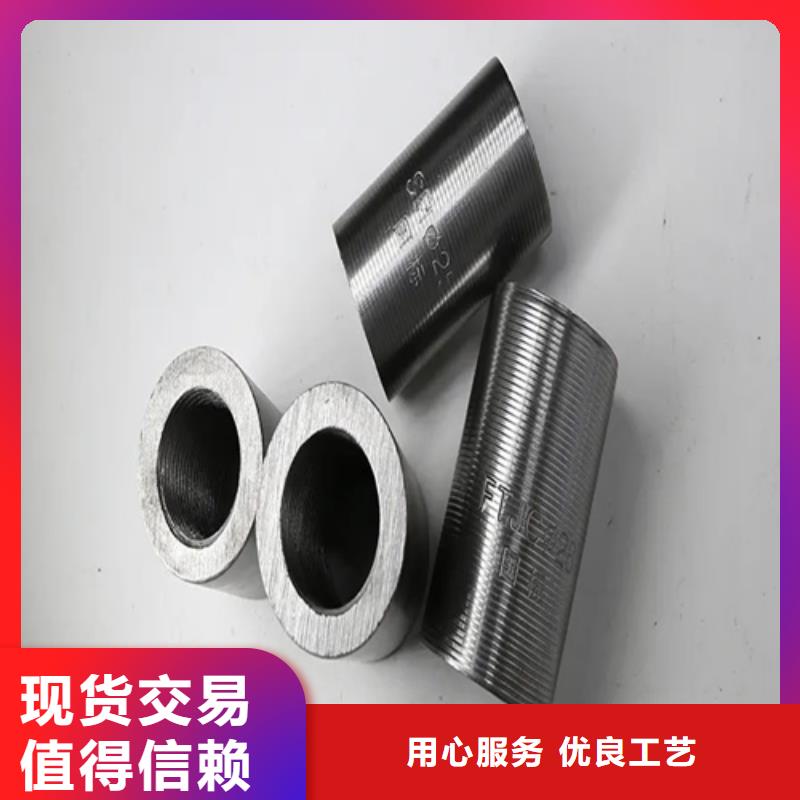

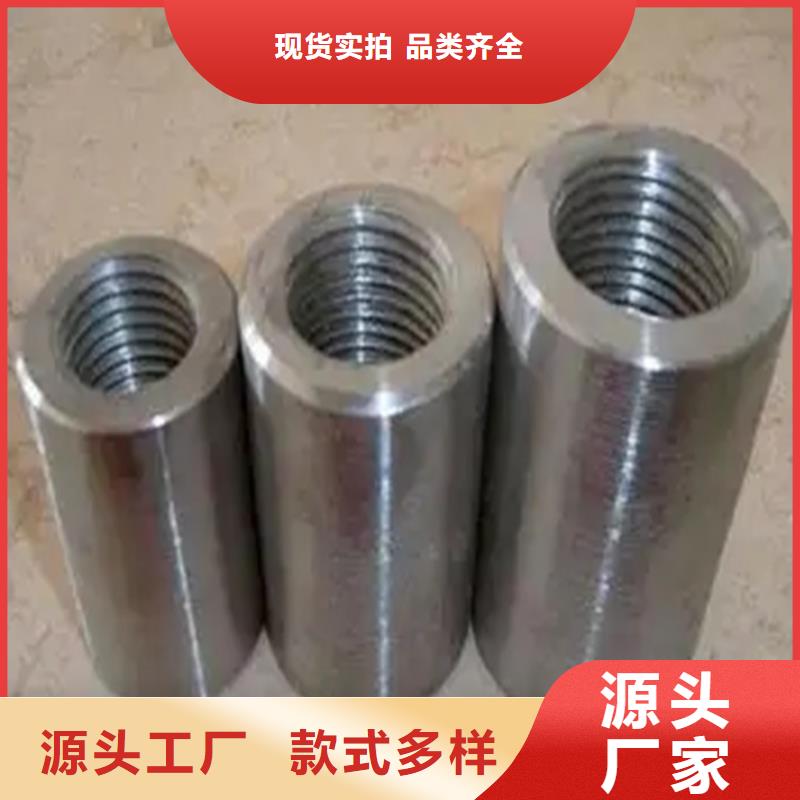

實物展示

專業的太原16的鋼筋套筒生產廠家為您提供一站式采購

PROFESSIONAL PRODUCT MANUFACTURERS PROVIDE YOU WITH ONE-STOP PROCUREMENT

工程案例

細節決定成敗,為您提供太原16的鋼筋套筒的解決方案

DETAILS DETERMINE SUCCESS OR FAILURE,PROVIDING YOU WITH PRODUCT SOLUTIONS

適用范圍廣

WIDE APPLICATION RANGE

17za.com

17za.com